Custom Carts and Material Handling Equipment

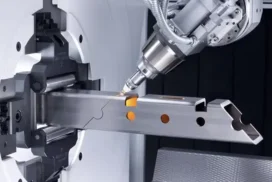

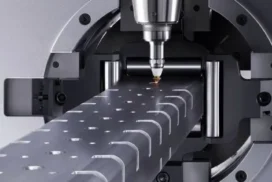

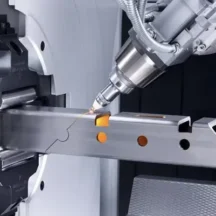

Sheet Metal and Tube Laser Cut Parts

At Plymouth Industries, we specialize in delivering CNC laser cutting services tailored to your needs. Our state-of-the-art fiber laser cutting technology always ensures exceptional quality, whether you require precision metal fabrication, intricate designs, sheet metal parts, or tube laser parts.

- Steel- up to 1.0" thick

- Stainless Steel - up to 3/8" thick

- Aluminum - up to 1/2" thick.

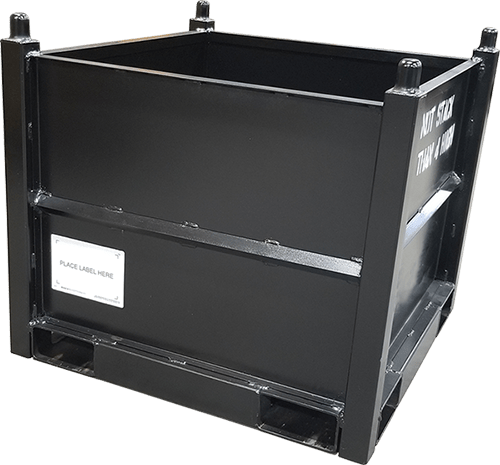

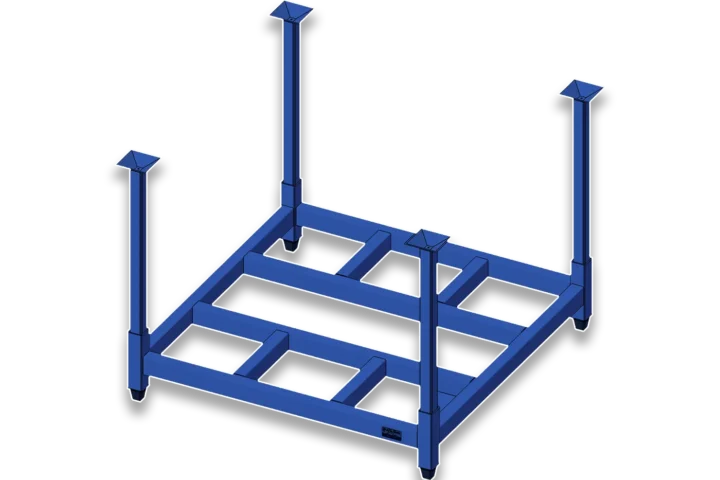

MaxStax Portable Stack Racks

- 4,000 lbs. maximum weight per rack.

- Stack up to six units to maximize cubic storage.

- Easily relocate empty or full racks with a forklift.

- Great for seasonal inventory, raw materials, finished goods, and more.

Manufacturing Capabilities

Plymouth Industries is a custom metal fabricator specializing in returnable shipping racks, racks and carts, industrial automation, machine building, materials handling solutions, and lifting devices.

Industrial Automation & Materials Handling Solutions

We improve your manufacturing process by the design and fabrication of industrial automation systems that increase efficiency and productivity.

- Design build machinery

- Custom conveyors (pick and place, in-feed, and out-feed systems)

- Pallet feeders/stackers

- Tunnel wrappers

- Robotic integration

- PLC control machinery and systems

- Below the hook certified lifting devices

- Lift truck attachments

Learn More...

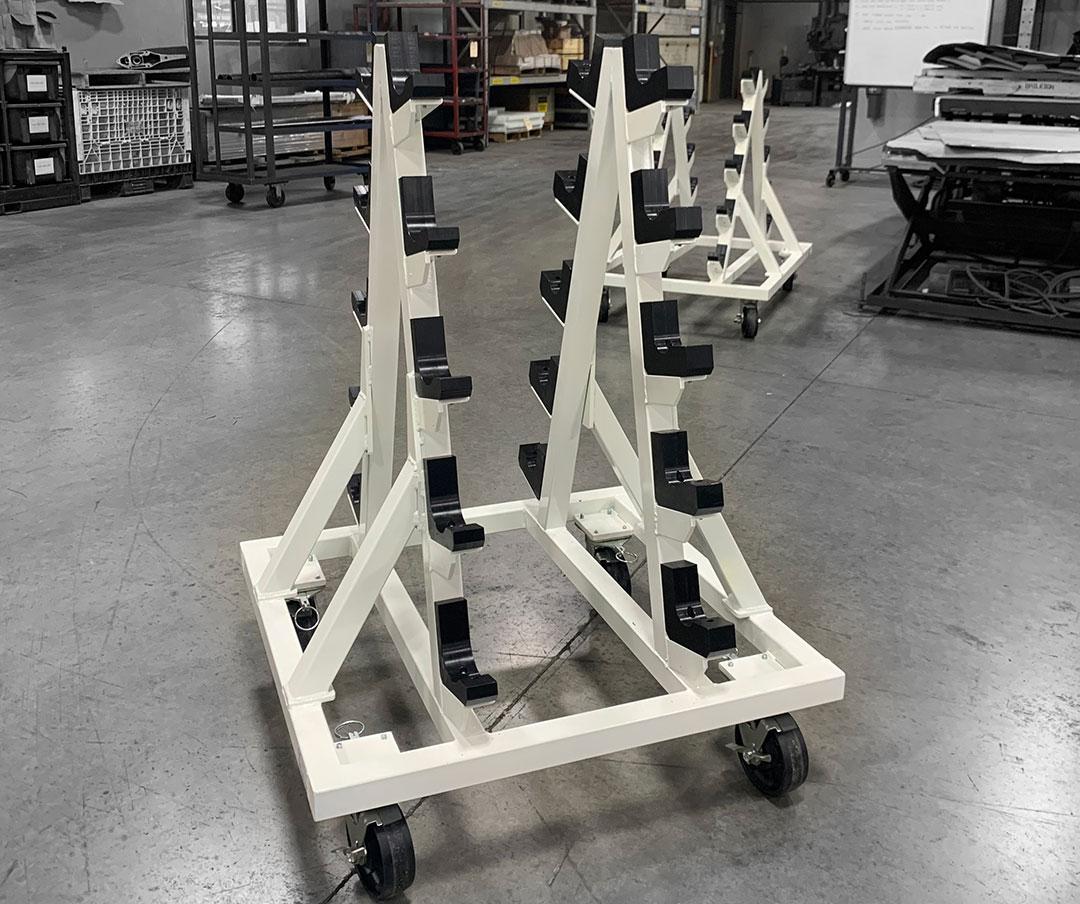

Custom Racks and Carts

If your logistical challenges require steel racks or carts, Plymouth Industries, Inc. will apply our engineering expertise to design a creative solution to meet your specific needs. We would be pleased to offer a FREE container study.

- Custom shipping racks

- Shipping carts

- Assembly carts

- In-process carts

- Smart carts

- Picking Cage

- Swivel Carts

- Full Wire Baskets

- Oven Carts

Learn More...

Product Line

Plymouth Industries, Inc. has engineered and developed several unique product lines that are used for industrial and residential applications.

- MaxStax Portable Stack Racks

- Driveway Entrance Barrier Gates

- Rack and post protector

- Barrier guards

- Roll out drawer storage racks

- GroundworX™

- Complete private labeled product lines and re-shoring opportunities.

Other Important Links

PlyInd News

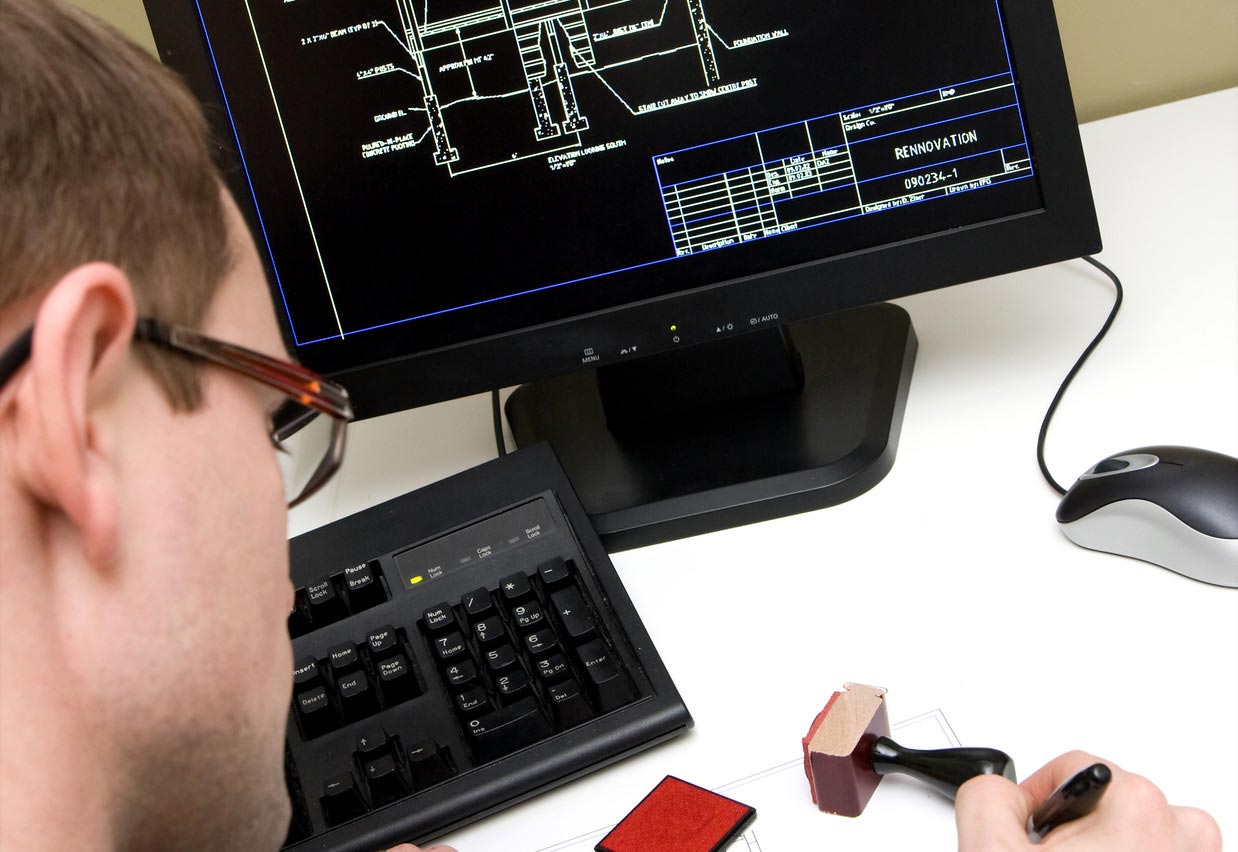

Mechanical Drafter

We are looking for a Mechanical Drafter to work with our team of Engineers and Project Manager to convert designs into technical plans. Drafter responsibilities include gathering drawings and specifications, calculating material and equipment requirements, and detailing prints to be used in production.

Custom Industrial Automation for High-Volume Manufacturing

In high-volume manufacturing environments, industrial automation plays a critical role in improving consistency, safety, and throughput. Plymouth Industries designs and builds custom industrial automation solutions that replace manual processes with fully integrated, automated workflows engineered around real-world production demands.This custom automation system was developed to streamline material handling, pressing, curing, storage, and unloading while maintaining tight process control and operator safety. By combining engineered equipment with intelligent controls, industrial automation systems help manufacturers increase efficiency without sacrificing reliability.

Wisconsin Tube Laser Cutting Services Built for Speed, Accuracy, and Cost Control

Manufacturers across the Midwest and beyond are under constant pressure to deliver high-quality parts faster and at lower cost, without sacrificing accuracy. Traditional fabrication methods often require multiple setups, secondary machining, and additional labor, which drive up prices and extend lead times. Tube laser cutting services solve these challenges by combining speed, precision, and efficiency into a single, streamlined process.At Plymouth Industries, tube laser cutting is designed to help OEMs, fabricators, and procurement teams reduce total manufacturing cost while receiving parts that meet exact specifications. By cutting tubes and angles in one automated operation, this capability supports faster turnaround, competitive pricing, and consistent results from prototype through production.

Certified Multi-Pronged Forklift Attachment for Core Handling

High-volume manufacturers in the industrial paper and packaging sector rely on safe, repeatable material-handling processes to move long paper tubes and cores efficiently. Standard forklift forks are not designed for these cylindrical products, often leading to instability, product damage, and reduced throughput.To solve this challenge, Plymouth Industries engineered and fabricated a certified 3-, 5-, and 7-pronged lift truck attachment specifically designed for handling paper cores in demanding production environments.

Custom Cart Engineered for Large Component Handling

Manufacturers in the heavy equipment and agricultural machinery space face ongoing challenges when moving oversized, high-value components through production and assembly. To support safe, efficient material flow, Plymouth Industries recently designed and fabricated a custom cart tailored for transporting large exterior body panels within a high-volume manufacturing environment.

Testimonials

Todd Scherich

Over the last several years, I have personally worked with Plymouth Industries, Inc. on field installation and special equipment applications. I have found them to be a good source of assistance, as they are constantly upgrading their service levels and technical support capabilities.

Their people are hardworking team players who think as well as work. They work safely and productively.

I appreciate our relationship and look forward to future projects.

Norma Sanchez

Over the course of fifteen years, while I was Plant Manager in three different locations, Lowel, Canandaigua and now Robesonia, I have employed Plymouth Industries, Inc. to assist us as follows: core bundling system/wrapper, core handling/probes, conveyors, step up roll down tables, core splitter saw, manual serpentine equipment, cart/racks and half highs, creels and creel enhancement, and powered roller tube accelerator, target and drop down.

Plymouth Industries, Inc. has proved to be a cost-effective and creative resource. Because they are competitive and confidential partners, I feel confident when I bring them to the table and have assisted with interfacing with our customers.

Mike Armitage

While I was Plant Manager in Pittsfield, I had the opportunity to team with Plymouth Industries, Inc. on the Half High Core Handling System.

This system was developed and implemented at our Pittsfield facility with great success and lasting benefits. The team of people put together by Al Borkenhagen, which included myself, engineering staff from Plymouth Industries, as well as additional Sonoco personnel.

The half high core handling system is easily implemented, has low maintenance costs and yields immediate results. I personally believe this system has positively impacted our bottom line.